Divine GraceBuilding Automation

In 2015 Johnson Heating and Cooling L.L.C. was contracted to design, build, and intall both a building automation system and a two boiler heating sytem at a church and school in Oakland County, Michigan.

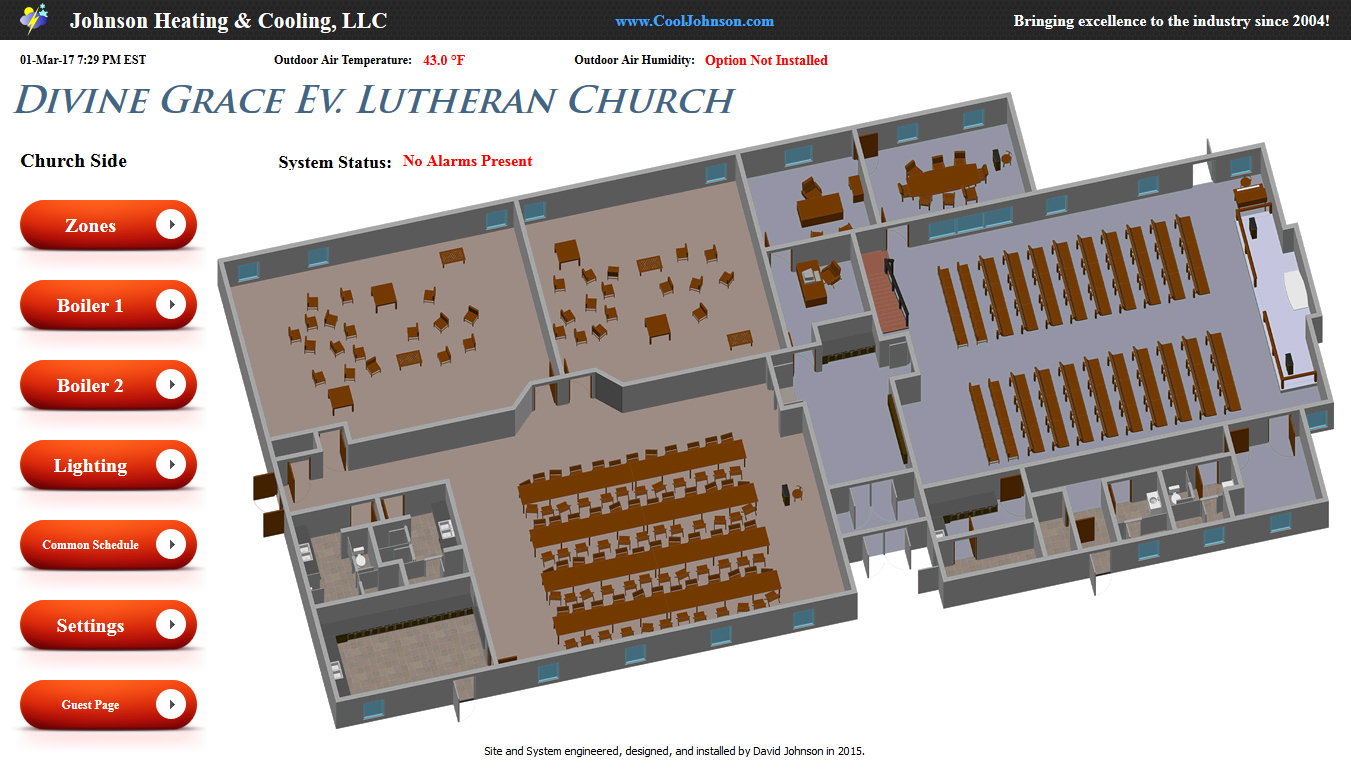

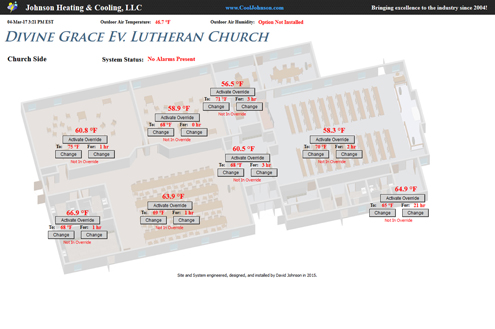

BAS Page

Tithing once is a good thing, but giving a tithe that keeps on giving is even better! So as not to seem disingenuous, we did get paid for the work that we did, although we also discount the cost of our services whenever we’re able to- if we feel that the cause is a worthy one. In some senses, it’s one way for us to tithe. We feel blessed that God has given us the opportunity to provide our services for His places of worship, and we take a special sort of pride with the work that we do in those structures. Divine Grace Ev. Lutheran Church and School is special to us because David Johnson Jr. (president of Johnson Heating and Cooling, LLC) himself attended Christian schools in his youth. We understand the mission and challenges of Christian churches which support the education of this country’s “next generation”, and we applaud and are grateful for all those who serve God via Christian education.

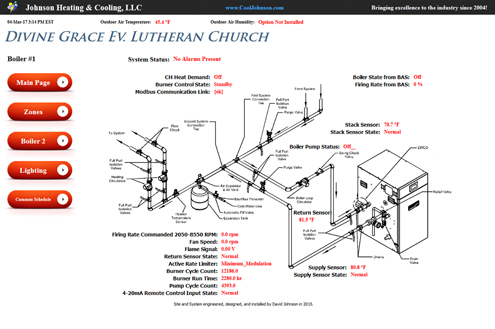

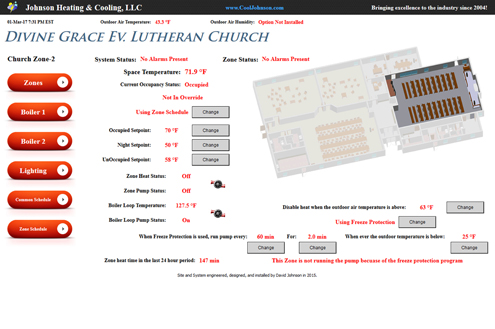

So it was mentioned, “...a tithe that keeps on giving...”. For this project, we were very busy at the time that the proposal was accepted, so we worked with a subcontractor (David Sr.’s company) to help us install the new boilers for the job before the weather shifted in the fall, although, we installed the automation system. From a monitary perspective, our portion of the contract was relatively small, however, it did have a great impact on the final project. It seems very common that many customers and also “would be customers” typically miss an important aspect when choosing options or contractors for certain work. The thing that we’ve seen many customers “miss” is the amortized difference in operational cost of the finished project based on both system structure and the difference in quality between contractors. While it’s understandable, at least to some extent, that a potential customer would not “have a crystal ball” and know ahead of time what kinds of differences could be expected based on using one contractor versus another, it still always seems to amaze me how some customers don’t consider the difference in value that one contractor may provide versus another. Consider the amortized cost difference over the next twenty years and then consider that when it comes to building automation systems, the difference in energy costs based on using one contractor versus another could be as much as 80%- it’s a curious thing to me. Check out CoolingLogic™ for substantiation of this claim. So, for Divine Grace, the boilers needed to be replaced, but also, we felt that it would be in the church’s best interest if they also had an automation system installed. Previously, the church used non-programmable thermostats that kept constant temperatures and had no reset. Providing for reset was problematic because the water in the pipes was very susceptible to freezing in the winter. Basically, if the temperature set points were set down to low settings, while the building was unoccupied, the heat/pumps would stay off for several hours. Because the piping for the radiant heating was near the exterior walls and because the building had a large thermal capacity, the pipes would freeze in the winter if the temperatures were reset. The outer perimeter would reduce in temperature to the point where the water in the pipes would freeze, but the heat would not come on because the center of the building would decrease in temperature more slowly and not call for heat until after the pipes were frozen. Due to the fact that pipes freezing was problematic, we had to work something out.